Advantages

![]() Real-time and automatic tracking of welding seams, no need for tracks or unmanned programming and teaching

Real-time and automatic tracking of welding seams, no need for tracks or unmanned programming and teaching

![]() Integrated design of robot system for a convenient transfer of equipment on site

Integrated design of robot system for a convenient transfer of equipment on site

![]() Junior welders can be proficient in operation after only two weeks of training, reducing labor costs

Junior welders can be proficient in operation after only two weeks of training, reducing labor costs

![]() Welding process database records to ensure the smooth implementation of process requirements and reduce management costs

Welding process database records to ensure the smooth implementation of process requirements and reduce management costs

![]() High-strength long-distance continuous welding, with smooth welding-seams, in a good and stable quality

High-strength long-distance continuous welding, with smooth welding-seams, in a good and stable quality

![]() For multi-scenario production tasks in horizontal welding, flat welding, vertical welding, overhead welding, curved surface welding and three-dimensional surface welding

For multi-scenario production tasks in horizontal welding, flat welding, vertical welding, overhead welding, curved surface welding and three-dimensional surface welding

Application

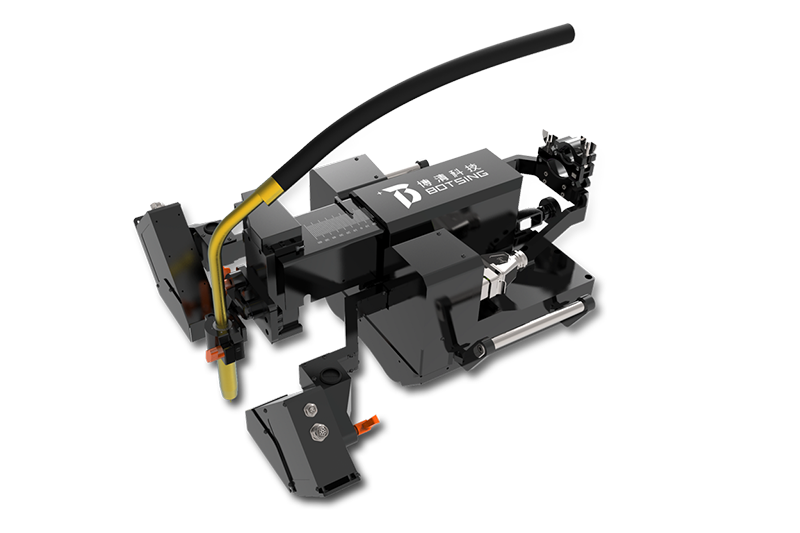

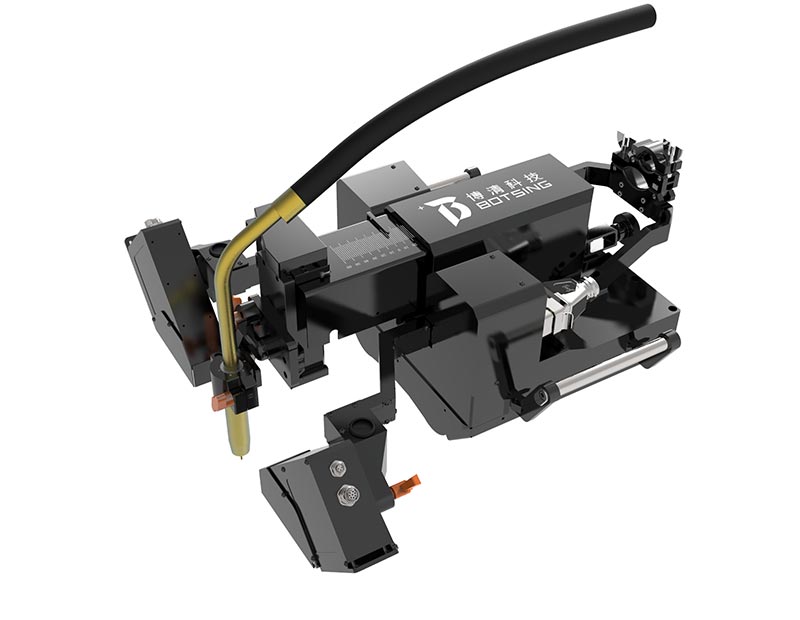

| ①BOT-WTA20-122 Application scenario: curved surfaces with a diameter greater than 800mm |

|

|

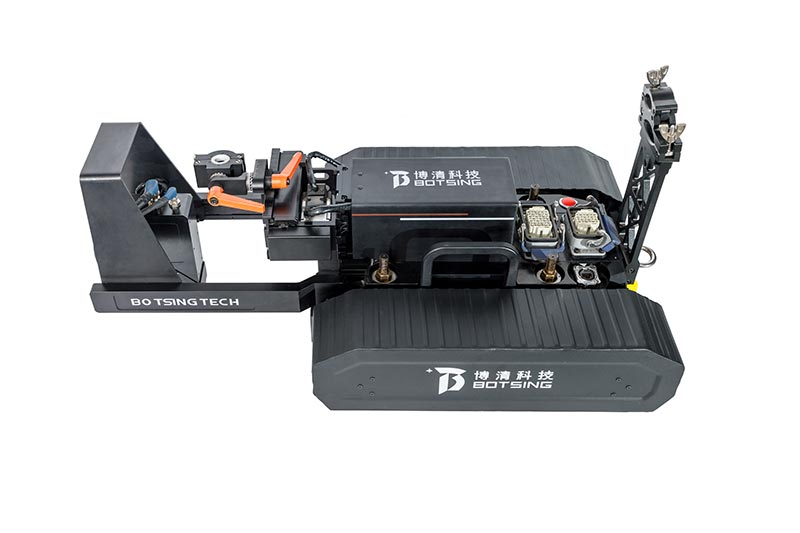

②BOT-WTA20-322 Application scenarios: horizontal and vertical seams of small and medium storage tanks, joint seams of hulls, etc. |

| ③BOT-WTA10-421 Application scenarios: three-dimensional surface welding such as end covers, spherical tanks, etc. |

|

| BOT-WTA20-122 | BOT-WTA20-322 | BOT-WTA10-421 | |

| Dimensions | 582*570*255(mm) | 480*620*310(mm) | 733*404*285(mm) |

| Weight | 20kg | 36kg | 34kg |

| Maximum load | 50kg | 55kg | 55kg |

| Diameter of walking surface | >800mm | >5000mm | >5000mm |

| Chassis structure | Wheeled chassis | Crawler chassis | Crawler chassis |

| Welding torch position | Side torch | Side torch | Side torch |

| Number of laser tracking systems | 2 | 2 | 1 |

| Accuracy of laser tracking system | ±0.2mm | ±0.2mm | ±0.2mm |